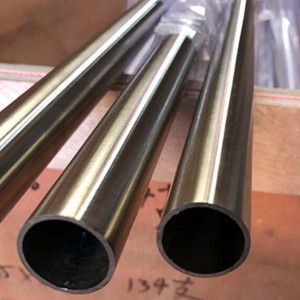

Paip Lancar Keluli Dupleks

Butiran Paip Lancar Keluli Dupleks

Apakah paip lancar keluli dupleks?

Keluli tahan karat dupleks dipanggil "dupleks" kerana ia mempunyai mikrostruktur dua fasa yang terdiri daripada butiran keluli tahan karat ferit dan austenit. Gambar menunjukkan fasa austenit kuning sebagai "pulau" yang dikelilingi oleh fasa ferit biru. Apabila keluli tahan karat dupleks dicairkan, ia memejal dari fasa cecair kepada struktur ferit sepenuhnya. Paip keluli tahan karat dupleks tergelek panas dan paip keluli tahan karat dupleks ditarik sejuk diperbuat daripada paip keluli tahan karat dupleks. Paip lancar keluli dupleks digunakan secara meluas dalam projek keperluan ketepatan tinggi. Paip lancar keluli dupleks adalah kuat dan sangat tahan kakisan. Terdapat pelbagai gred paip keluli tahan karat dupleks dengan sifat mekanikal yang berbeza.

Komposisi Kimia Paip Lancar Keluli Dupleks

| C | N | P | Si | Mn | Mo | Fe | Cr | S | Ni |

| 1.0 | 0.03 | 0.02 | 2.0 | 3.0 - 3.5 | 22.0 - 23.0 | 0.03 | 4.5 - 6.5 | 0.14 - 0.2 | Bal |

Ciri-ciri Mekanikal Paip Lancar Keluli Dupleks

| Ketumpatan Paip | Takat Lebur Paip | Kekuatan Hasil (Offset 0.2%) | Kekuatan Tegangan | Pemanjangan |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi - 80000 , MPa - 550 | Psi - 116000 , MPa - 800 | 15% |

Carta Saiz Paip Lancar Keluli Dupleks

| NPS | Diameter Luar | Ketebalan Dinding | ||

| in | mm | in | mm | |

| 1/2″ | 0.84 | 21 | 0.109 | 2.769 |

| 0.147 | 3.734 | |||

| 3/4″ | 1.05 | 27 | 0.113 | 2.87 |

| 0.154 | 3.912 | |||

| 1 inci | 1.315 | 33 | 0.133 | 3.378 |

| 0.179 | 4.547 | |||

| 1 1/4″ | 1.66 | 42 | 0.14 | 3.556 |

| 0.191 | 4.851 | |||

| 1 1/2″ | 1.9 | 48 | 0.145 | 3.683 |

| 0.2 | 5.08 | |||

| 2 inci | 2.375 | 60 | 0.154 | 3.912 |

| 0.218 | 5.537 | |||

| 2 1/2″ | 2.875 | 73 | 0.203 | 5.516 |

| 0.276 | 7.01 | |||

| 3 inci | 3.5 | 89 | 0.216 | 5.486 |

| 0.3 | 7.62 | |||

| 4 inci | 4.5 | 114 | 0.237 | 6.02 |

| 0.337 | 8.56 | |||

| 6 inci | 6.625 | 168 | 0.188 | 4.775 |

| 0.203 | 5.516 | |||

| 0.219 | 5.563 | |||

| 0.25 | 6.35 | |||

| 0.28 | 7.112 | |||

| 0.312 | 7.925 | |||

| 0.375 | 9.525 | |||

| 0.432 | 10.973 | |||

| 0.5 | 12.7 | |||

| 8 inci | 8.625 | 219 | 0.188 | 4.775 |

| 0.203 | 5.156 | |||

| 0.219 | 5.563 | |||

| 0.25 | 6.35 | |||

| 0.277 | 7.036 | |||

| 0.322 | 8.179 | |||

| 0.375 | 9.525 | |||

| 0.406 | 10.312 | |||

| 0.5 | 12.7 | |||

| 10 inci | 10.75 | 273 | 0.188 | 4.775 |

| 0.219 | 5.563 | |||

| 0.25 | 6.35 | |||

| 0.307 | 7.798 | |||

| 0.344 | 8.738 | |||

| 0.365 | 9.271 | |||

| 0.438 | 11.125 | |||

| 0.5 | 12.7 | |||

| 0.594 | 15.088 | |||

| 12 inci | 12.75 | 324 | 0.188 | 4.775 |

| 0.219 | 5.563 | |||

| 0.25 | 6.35 | |||

| 0.281 | 7.137 | |||

| 0.312 | 7.925 | |||

| 0.375 | 9.525 | |||

| 0.406 | 10.312 | |||

| 0.5 | 12.7 | |||

| 0.562 | 14.275 | |||

| 14 inci | 14 | 356 | 0.188 | 4.775 |

| 0.219 | 5.563 | |||

| 0.25 | 6.35 | |||

| 0.281 | 7.137 | |||

| 0.312 | 7.925 | |||

| 0.375 | 9.525 | |||

| 0.438 | 11.125 | |||

| 0.5 | 12.7 | |||

| 0.625 | 15.875 | |||

| 16 inci | 16 | 406 | 0.188 | 4.775 |

| 0.219 | 5.563 | |||

| 0.25 | 6.35 | |||

| 0.281 | 7.137 | |||

| 0.312 | 7.925 | |||

| 0.344 | 8.738 | |||

| 0.375 | 9.525 | |||

| 0.438 | 11.125 | |||

| 0.5 | 12.7 | |||

| 18 inci | 18 | 457 | 0.219 | 5.563 |

| 0.25 | 6.35 | |||

| 0.281 | 7.137 | |||

| 0.312 | 7.925 | |||

| 0.375 | 9.525 | |||

| 0.438 | 11.125 | |||

| 0.5 | 12.7 | |||

| 0.562 | 14.275 | |||

| 0.625 | 15.875 | |||

| 20 inci | 20 | 508 | 0.25 | 6.35 |

| 0.282 | 7.163 | |||

| 0.312 | 7.925 | |||

| 0.375 | 9.525 | |||

| 0.438 | 11.125 | |||

| 0.5 | 12.7 | |||

| 0.594 | 15.088 | |||

| 0.625 | 15.875 | |||

| 0.688 | 17.475 | |||

| 24 inci | 24 | 610 | 0.25 | 6.35 |

| 0.281 | 7.137 | |||

| 0.312 | 7.925 | |||

| 0.375 | 9.525 | |||

| 0.438 | 11.125 | |||

| 0.5 | 12.7 | |||

| 0.625 | 15.875 | |||

| 0.688 | 17.475 | |||

| 0.75 | 19.05 | |||

| 30 inci | 30 | 762 | 0.25 | 6.35 |

| 0.281 | 7.137 | |||

| 0.312 | 7.925 | |||

| 0.375 | 9.525 | |||

| 0.438 | 11.125 | |||

| 0.5 | 12.7 | |||

| 0.625 | 15.875 | |||

| 0.688 | 17.475 | |||

| 0.75 | 19.05 | |||

| 36 inci | 36 | 914 | 0.25 | 6.35 |

| 0.281 | 7.137 | |||

| 0.312 | 7.925 | |||

| 0.375 | 9.525 | |||

| 0.438 | 11.125 | |||

| 0.5 | 12.7 | |||

| 0.625 | 15.875 | |||

| 0.688 | 17.475 | |||

| 0.75 | 19.05 | |||

| 42 inci | 42 | 1067 | 0.312 | 7.925 |

| 0.375 | 9.525 | |||

| 0.5 | 12.7 | |||

| 0.75 | 19.05 | |||

| 48 inci | 48 | 1219 | 0.375 | 9.525 |

| 0.438 | 11.125 | |||

| 0.5 | 12.7 | |||

| 0.75 | 19.05 | |||

| 0.875 | 22.225 | |||

Penggunaan Paip Lancar Keluli Dupleks

- Saluran Paip Minyak dan Gas

- Industri Kimia

- Kerja paip

- Pemanasan

- Sistem Bekalan Air

- Loji Janakuasa

- Industri Kertas & Pulpa

- Aplikasi Tujuan Umum

- Industri Fabrikasi

- Industri Pemprosesan Makanan

- Struktur Keluli