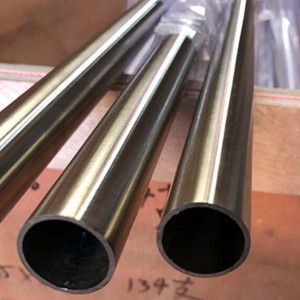

Duplex Steel Seamless Pipe

Details of Duplex Steel Seamless Pipe

What is a duplex steel seamless pipe?

Duplex stainless steels are called “duplex” because they have a two-phase microstructure consisting of grains of ferritic and austenitic stainless steel. The picture shows the yellow austenitic phase as “islands” surrounded by the blue ferritic phase. When duplex stainless steel is melted it solidifies from the liquid phase to a completely ferritic structure. Hot-rolled duplex stainless steel pipe and cold-drawn duplex stainless pipe made up of duplex stainless steel pipe. Duplex steel seamless pipe is widely used in the high-precision requirements project. Duplex steel seamless pipes are both strong and highly corrosion-resistant. There are various grades of duplex stainless steel pipes with different mechanical properties.

Chemical Composition of Duplex Steel Seamless Pipe

| C | N | P | Si | Mn | Mo | Fe | Cr | S | Ni |

| 1.0 | 0.03 | 0.02 | 2.0 | 3.0 - 3.5 | 22.0 - 23.0 | 0.03 | 4.5 - 6.5 | 0.14 - 0.2 | Bal |

Mechanical Characteristics of Duplex Steel Seamless Pipe

| Pipe Density | Pipe Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi - 80000 , MPa - 550 | Psi - 116000 , MPa - 800 | 15 % |

Size Chart of Duplex Steel Seamless Pipe

| NPS | Outside Diameter | Wall Thickness | ||

| in | mm | in | mm | |

| 1/2″ | 0.84 | 21 | 0.109 | 2.769 |

| 0.147 | 3.734 | |||

| 3/4″ | 1.05 | 27 | 0.113 | 2.87 |

| 0.154 | 3.912 | |||

| 1″ | 1.315 | 33 | 0.133 | 3.378 |

| 0.179 | 4.547 | |||

| 1 1/4″ | 1.66 | 42 | 0.14 | 3.556 |

| 0.191 | 4.851 | |||

| 1 1/2″ | 1.9 | 48 | 0.145 | 3.683 |

| 0.2 | 5.08 | |||

| 2″ | 2.375 | 60 | 0.154 | 3.912 |

| 0.218 | 5.537 | |||

| 2 1/2″ | 2.875 | 73 | 0.203 | 5.516 |

| 0.276 | 7.01 | |||

| 3″ | 3.5 | 89 | 0.216 | 5.486 |

| 0.3 | 7.62 | |||

| 4″ | 4.5 | 114 | 0.237 | 6.02 |

| 0.337 | 8.56 | |||

| 6″ | 6.625 | 168 | 0.188 | 4.775 |

| 0.203 | 5.516 | |||

| 0.219 | 5.563 | |||

| 0.25 | 6.35 | |||

| 0.28 | 7.112 | |||

| 0.312 | 7.925 | |||

| 0.375 | 9.525 | |||

| 0.432 | 10.973 | |||

| 0.5 | 12.7 | |||

| 8″ | 8.625 | 219 | 0.188 | 4.775 |

| 0.203 | 5.156 | |||

| 0.219 | 5.563 | |||

| 0.25 | 6.35 | |||

| 0.277 | 7.036 | |||

| 0.322 | 8.179 | |||

| 0.375 | 9.525 | |||

| 0.406 | 10.312 | |||

| 0.5 | 12.7 | |||

| 10″ | 10.75 | 273 | 0.188 | 4.775 |

| 0.219 | 5.563 | |||

| 0.25 | 6.35 | |||

| 0.307 | 7.798 | |||

| 0.344 | 8.738 | |||

| 0.365 | 9.271 | |||

| 0.438 | 11.125 | |||

| 0.5 | 12.7 | |||

| 0.594 | 15.088 | |||

| 12″ | 12.75 | 324 | 0.188 | 4.775 |

| 0.219 | 5.563 | |||

| 0.25 | 6.35 | |||

| 0.281 | 7.137 | |||

| 0.312 | 7.925 | |||

| 0.375 | 9.525 | |||

| 0.406 | 10.312 | |||

| 0.5 | 12.7 | |||

| 0.562 | 14.275 | |||

| 14″ | 14 | 356 | 0.188 | 4.775 |

| 0.219 | 5.563 | |||

| 0.25 | 6.35 | |||

| 0.281 | 7.137 | |||

| 0.312 | 7.925 | |||

| 0.375 | 9.525 | |||

| 0.438 | 11.125 | |||

| 0.5 | 12.7 | |||

| 0.625 | 15.875 | |||

| 16” | 16 | 406 | 0.188 | 4.775 |

| 0.219 | 5.563 | |||

| 0.25 | 6.35 | |||

| 0.281 | 7.137 | |||

| 0.312 | 7.925 | |||

| 0.344 | 8.738 | |||

| 0.375 | 9.525 | |||

| 0.438 | 11.125 | |||

| 0.5 | 12.7 | |||

| 18″ | 18 | 457 | 0.219 | 5.563 |

| 0.25 | 6.35 | |||

| 0.281 | 7.137 | |||

| 0.312 | 7.925 | |||

| 0.375 | 9.525 | |||

| 0.438 | 11.125 | |||

| 0.5 | 12.7 | |||

| 0.562 | 14.275 | |||

| 0.625 | 15.875 | |||

| 20″ | 20 | 508 | 0.25 | 6.35 |

| 0.282 | 7.163 | |||

| 0.312 | 7.925 | |||

| 0.375 | 9.525 | |||

| 0.438 | 11.125 | |||

| 0.5 | 12.7 | |||

| 0.594 | 15.088 | |||

| 0.625 | 15.875 | |||

| 0.688 | 17.475 | |||

| 24″ | 24 | 610 | 0.25 | 6.35 |

| 0.281 | 7.137 | |||

| 0.312 | 7.925 | |||

| 0.375 | 9.525 | |||

| 0.438 | 11.125 | |||

| 0.5 | 12.7 | |||

| 0.625 | 15.875 | |||

| 0.688 | 17.475 | |||

| 0.75 | 19.05 | |||

| 30″ | 30 | 762 | 0.25 | 6.35 |

| 0.281 | 7.137 | |||

| 0.312 | 7.925 | |||

| 0.375 | 9.525 | |||

| 0.438 | 11.125 | |||

| 0.5 | 12.7 | |||

| 0.625 | 15.875 | |||

| 0.688 | 17.475 | |||

| 0.75 | 19.05 | |||

| 36″ | 36 | 914 | 0.25 | 6.35 |

| 0.281 | 7.137 | |||

| 0.312 | 7.925 | |||

| 0.375 | 9.525 | |||

| 0.438 | 11.125 | |||

| 0.5 | 12.7 | |||

| 0.625 | 15.875 | |||

| 0.688 | 17.475 | |||

| 0.75 | 19.05 | |||

| 42″ | 42 | 1067 | 0.312 | 7.925 |

| 0.375 | 9.525 | |||

| 0.5 | 12.7 | |||

| 0.75 | 19.05 | |||

| 48″ | 48 | 1219 | 0.375 | 9.525 |

| 0.438 | 11.125 | |||

| 0.5 | 12.7 | |||

| 0.75 | 19.05 | |||

| 0.875 | 22.225 | |||

Application of Duplex Steel Seamless Pipe

- Oil and Gas Pipeline

- Chemical Industry

- Plumbing

- Heating

- Water Supply Systems

- Power Plant

- Paper & Pulp Industry

- General Purpose Applications

- Fabrication Industry

- Food Processing Industry

- Steel Structural