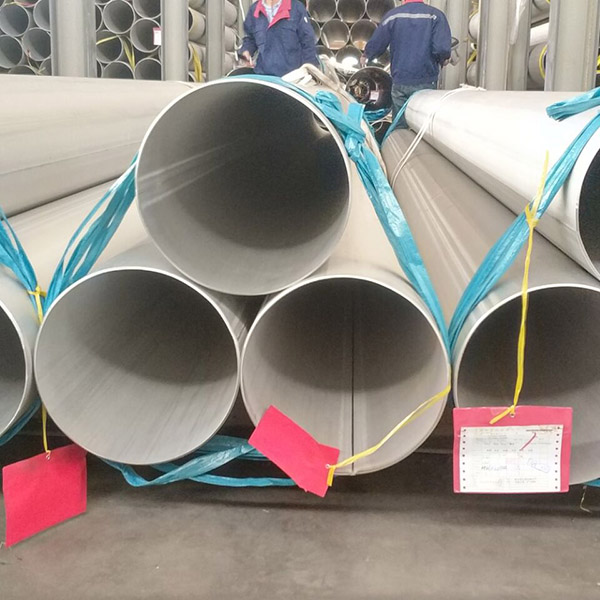

Stainless Steel Welded Pipe

Product Descripition

What is Stainless Steel Welded Pipe

Low-cost and corrosion resistance material manufactured by stainless steel pipe. It's applied in various industries for different parts. Not only is it durable and long-lasting with a perfect surface finish, but it also has excellent strength.

Stainless steel welded pipes have rust resistance and excellent high-temperature resistance. It is made from the finest materials and is designed for industrial use. We have various ranges of dimensions to suit most applications, such as oil, chemical, medicine, and food.

Product Specification

Available Specification

| Product Name | Executive Standard | Dimension | Steel Code / Steel Grade |

| Industrial Pipes | ASTM A312, A358, A778, JIS G3459 | OD: 1/4"~40" WT: SCH5S~SCH80S |

TP304, TP304L, TP316L, SUS304TP |

| Tubes for Boiler and Heat-Exchanger, General Service Tubing | ASTM A249, A269, JIS G3463 | OD: 15.9~139.8mm WT: 1.6~5.0mm |

TP304, TP304L, TP316L, SUS304TB |

| Mechanical and Structural Tubes | ASTM A554, JIS G3446 | OD: 7.9~152.4mm WT: 0.5~6.5mm |

MT304, MT304L, MT316L, MT430 Grade 201, 202 as per mill's STD SUS304 |

| Square Tubes | ASTM A554 | OD: 12.7x12.7~150x150mm WT: 0.7~6.5mm |

MT304, MT304L, MT316L, MT430 Grade 201, 202 as per mill's STD |

| Rectangular Tubes | ASTM A554 | OD: 10x20~100x200mm WT: 0.7~6.5mm |

MT304, MT304L, MT316L, MT430 Grade 201, 202 as per mill's STD |

| Sanitary Tubing | ASTM A270 JIS G3447 |

OD: 25.4~165.2mm WT: 0.8~3.05mm |

TP304, TP304L, TP316L, SUS304TBS |

| Large Gauge Pipes for Ordinary Piping | JIS G3448 | OD: 15.88~318.5mm WT: 0.8~3.0mm |

SUS304TPD |

| Large Diameter Pipes | JIS G3468 | OD: 14"~40" WT: SCH5S~SCH40S |

SUS304TPY |

Chemical Composition

Chemical Composition of ASTM A554 Stainless Steel Welded Pipe

| UNS | Grade | Carbon | Manganese | Phosphorus | Sulfur | Silicon | Nickel | Chromium | Molybdenum |

| S3165 | MT-304 | 0.08 | 2.0 | 0.045 | 0.03 | 1.0 | 8.0–11.0 | 18.0–20.0 | ... |

| MT-304L | 0.035B | 2.0 | 0.045 | 0.03 | 1.0 | 8.0–13.0 | 18.0–20.0 | ... | |

| MT-316 | 0.08 | 2.0 | 0.045 | 0.03 | 1.0 | 10.0–14.0 | 16.0–18.0 | 2.0–3.0 | |

| MT-316L | 0.035B | 2.0 | 0.045 | 0.03 | 1.0 | 10.0–15.0 | 16.0–18.0 | 2.0–3.0 |

Chemical Composition of ASTM A312 Stainless Steel Welded Pipe

| Grade | UNS Designation |

Composition | |||||||

| Carbon | Manganese | Phosphorous | Sulfur | Silicon | Chromium | Nickel | Molybdenum | ||

| TP304 | S30400 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0 – 20.00 | 8.0-11.0 | ... |

| TP304L | S30403 | 0.035 D | 2.00 | 0.045 | 0.03 | 1.00 | 18.0 – 20.00 | 8.0-113.0 | ... |

| TP304H | S30409 | 0.04 – 0.10 | 2.00 | 0.045 | 0.03 | 1.00 | 18.0 – 20.00 | 8.0-11.0 | ... |

| ... | S30415 | 0.04 – 0.06 | 0.8 | 0.045 | 0.03 | 1.00 –2.00 | 18.0 – 19.0 | 9.0-10.0 | ... |

| TP304N | S30451 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 18.0 – 20.00 | 8.0-18.0 | ... |

| TP304LN | S30453 | 0.035 | 2.00 | 0.045 | 0.03 | 1.00 | 18.0 – 20.00 | 8.0-12.0 | ... |

| TP316 | S31600 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 16.0-18.0 | 11.0-14.0E | ... |

| TP316L | S31603 | 0.035 D | 2.00 | 0.045 | 0.03 | 1.00 | 16.0-18.0 | 10.0-14.0 | ... |

| TP316H | S31609 | 0.04 – 0.10 | 2.00 | 0.045 | 0.03 | 1.00 | 16.0-18.0 | 10.0-14.0E | ... |

| TP316Ti | S31635 | 0.08 | 2.00 | 0.045 | 0.03 | 0.75 | 16.0-18.0 | 10.0-14.0 | 53 (C+N) –0.70 |

| TP316N | S31651 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 16.0-18.0 | 11.0-14.0E | ... |

| TP316LN | S31635 | 0.035 | 2.00 | 0.045 | 0.03 | 1.00 | 16.0-18.0 | 11.0-14.0E | ... |

Mechanical Properties

Mechanical Properties of ASTM A554 Stainless Steel Welded Pipe

| Grade | Tensile Strength, min | Yield Strength, min | ||

| ksi | MPa | ksi | MPa | |

| MT 429 and MT 430 | 60 | 414 | 35 | 241 |

| MT-430-Ti | 60 | 414 | 30 | 207 |

| MT 304L & MT 316L | 70 | 483 | 25 | 172 |

| S31655 | 92 | 635 | 45 | 310 |

| All other austenitic steels | 75 | 517 | 30 | 207 |

| MT 409 | 55 | 379 | 30 | 207 |

| All other ferritic | 60 | 414 | 35 | 241 |

| S31803 | 90 | 620 | 65 | 450 |

| S32003 | 100 | 690 | 70 | 485 |

| S32202 | 94 | 650 | 65 | 450 |

| S32205 | 95 | 655 | 65 | 450 |

| S32304 | 87 | 600 | 58 | 400 |

| S32550 | 110 | 760 | 80 | 550 |

| S32750 | 116 | 795 | 80 | 550 |

| S32760 | 108 | 750 | 80 | 550 |

| S81921 | 90 | 620 | 65 | 450 |

| S82011 | 101 | 700 | 75 | 515 |

Mechanical Properties of ASTM A312 Stainless Steel Welded Pipe

| Grade | UNS Designation |

Tensile Strength min, ksi [MPa] |

Yield Strength, min, ksi [MPa] |

| TP304 | S30400 | 75[515] | 30[205] |

| TP304L | S30403 | 70[485] | 25[170] |

| TP304H | S30409 | 75[515] | 30[205] |

| . . . | S30415 | 87[600] | 42[290] |

| TP304N | S30451 | 80[550] | 35[240] |

| TP304LN | S30453 | 75[515] | 30[205] |

| TP316 | S31600 | 75[515] | 30[205] |

| TP316L | S31603 | 70[485] | 25[170] |

| TP316H | S31609 | 75[515] | 30[205] |

| . . . | S31635 | 75[515] | 30[205] |

| TP316N | S31651 | 80[550] | 35[240] |

| TP316LN | S31653 | 75[515] | 30[205] |

Application

Stainless steel pipe (tube) has excellent characteristics of corrosion resistance and smooth finishing. Stainless steel pipe (tube) is commonly used in demanding equipment like automobiles, food processing, water treatment facilities, oil and gas processing, refinery and petrochemicals, breweries and energy industries.

- Automotive industries

- Food processing

- Water treatment facilities

- Breweries and energy industries

Size Chart of Stainless Steel Welded Pipe

| NPS Designator | Outside Diameter in. | Schedule 5S in. | Schedule 10S in. | Schedule 40S in. | Schedule 80S in. |

| 1/4 | 0.54 | 0.065 | 0.088 | 0.119 | |

| 3/8 | 0.675 | 0.065 | 0.091 | 0.126 | |

| 1/2 | 0.84 | 0.065 | 0.083 | 0.109 | 0.147 |

| 3/4 | 1.05 | 0.065 | 0.083 | 0.113 | 0.154 |

| 1.0 | 1.315 | 0.065 | 0.109 | 0.133 | 0.179 |

| 1 1/4 | 1.66 | 0.065 | 0.109 | 0.14 | 0.191 |

| 1 1/2 | 1.9 | 0.065 | 0.109 | 0.145 | 0.2 |

| 2 | 2.375 | 0.065 | 0.109 | 0.154 | 0.218 |

| 2 1/2 | 2.875 | 0.083 | 0.12 | 0.203 | 0.276 |

| 3 | 3.5 | 0.083 | 0.12 | 0.216 | 0.3 |

| 3 1/2 | 4 | 0.083 | 0.12 | 0.226 | 0.318 |

| 4 | 4.5 | 0.083 | 0.12 | 0.237 | 0.337 |

| 5 | 5.563 | 0.109 | 0.134 | 0.258 | 0.375 |

| 6 | 6.625 | 0.109 | 0.134 | 0.28 | 0.432 |

| 8 | 8.625 | 0.109 | 0.148 | 0.322 | 0.5 |

| 10 | 10.75 | 0.134 | 0.165 | 0.365 | 0.5 |

| 12 | 12.75 | 0.156 | 0.18 | 0.375 | 0.5 |

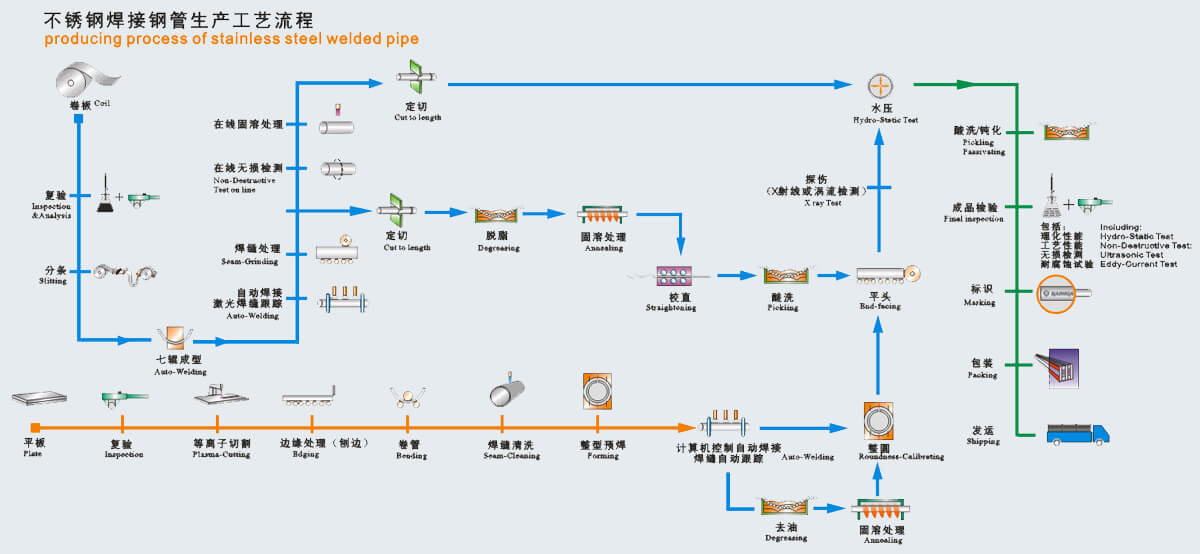

Manufacturing Process of Stainless Steel Welded Pipe:

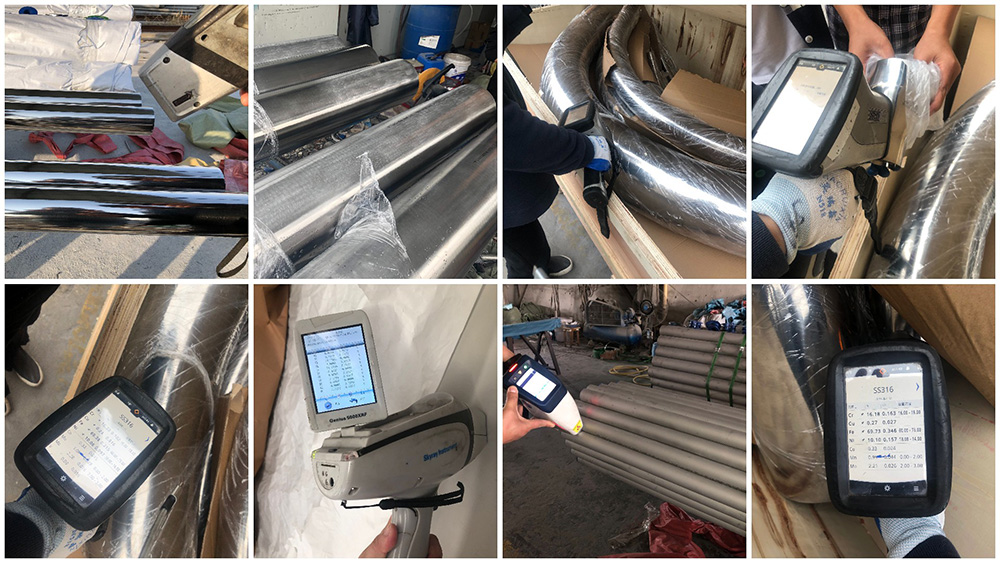

Test:

PMI test