News

-

Application fields of seamless stainless steel pipes and description of their advantages

Since seamless stainless steel pipes have superior safety, reliability, hygiene, environmental protection, economy, and other functions, they will gradually become the best choice for water supply pipe materials! Then let’s elaborate on where its advantages are reflected: 1: It can work saf...Read more -

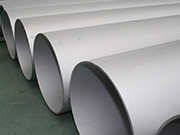

Details of S32205 stainless steel welded steel pipe in industrial projects

S32205 stainless steel welded steel pipe is formed by rolling 2205 stainless steel strip. 2205 steel pipe is duplex stainless steel composed of 21% chromium, 2.5% molybdenum, and 4.5% nickel-nitrogen alloy. It has high strength, good impact toughness, and good overall and local stress corrosion r...Read more -

Common A333Gr6 seamless steel pipe details in industrial projects

A333Gr.6 seamless steel pipe is an important material widely used in the field of fluid transportation such as oil and natural gas. Its excellent performance and wide application fields make it play a pivotal role in the industry. Below we will introduce the manufacturing process, performance cha...Read more -

Details of commonly used Q235B square steel pipes

In today’s industrial field, Q235B square steel pipe, as a widely used metal material, has become an indispensable part of many engineering projects with its unique performance and wide application scenarios. This article will give a comprehensive introduction to Q235B square steel pipe, in...Read more -

What are the differences between zinc plating, cadmium plating, chromium plating, and nickel plating in the processing technology of steel pipes

First, zinc plating: Features: Zinc is relatively stable in dry air and is not easy to change color. In water and humid atmospheres, it reacts with oxygen or carbon dioxide to form oxides or alkaline zinc carbonate films, which can prevent zinc from continuing to be plated and oxidized, and play ...Read more -

Advantages and disadvantages of 12 common flanges

First, a basic introduction to flanges Pipe flanges and their gaskets and fasteners are collectively referred to as flange joints. 1. Application: Flange joints are a very common and widely used component in engineering design. It is an indispensable part of piping design, pipe fittings, and valv...Read more