Carbon Steel Plate

Basic Introduction

What is the carbon steel plate?

Carbon steel plates are made from an alloy comprised of iron and carbon. Carbon Steel Plate is one of the most commonly used steels in the industry. Alloy steels can contain a variety of elements including chromium, nickel, and vanadium. According to The American Iron and Steel Institute, Steel can be defined as carbon steel when no minimum content is specified or required for chromium, cobalt, columbium, molybdenum, nickel, titanium, tungsten, vanadium, zirconium, or any other element that would be used to achieve an alloying effect. There are three types of carbon steel plates. Here are the details.

Low Carbon Steel Plate (0.05 < C ≤ 0.25%)

Low carbon steel plate, also known as mild carbon steel plate, is the cheapest and most widely used kind of carbon steel. With a carbon content of less than 0.25%, it is relatively weaker and softer but more fabricable, and easy to process, such as forging, welding, cutting, etc. Low carbon steel plate is mainly used in construction, machinery manufacturing, container manufacturing, shipbuilding, bridge construction, some parts of tractors and welding components, etc. The common codes are Q195, Q215, Q235, Q255, Q275, etc.

Medium Carbon Steel Plate (0.25% < C ≤ 0.6%)

Medium carbon steel plate refers to steel with a high carbon content of 0.25-0.6% and a small manganese content of 0.6-1.65%, which can increase the steel’s stress resistance. It provides a balance between low and high-carbon steel plates, offering greater strength and hardness than low-carbon steel while remaining more ductile than high-carbon steel. Medium carbon steel plate is popular in manufacturing various mechanical parts, such as axles, gears, or building materials.

High Carbon Steel Plate (C > 0.6%)

Commonly known as carbon tool steel, high carbon steel plate tends to have a carbon content of 0.6-1.25% and manganese of 0.3-0.9%, which can be hardened and tempered. By comparison, high-carbon steel provides the greatest strength and hardness but the lowest ductility. It means that the high-carbon steel plate is very difficult to weld, cut, bend, etc. Therefore, it is mainly used to manufacture smaller parts, iron wires, iron rings, cutting tools, high-strength wires and springs, and more.

Carbon Steel Plate

| Standard | ASTM A36, ASTM A283, ASTM A1008, ASTM A285, ASTM A515, ASTM A516,JIS G3141 and so on |

| Grade | ASTM A36, Gr. A. B. C. D Gr 55, 60, 65, 70, Q235B, Q355B, and so on |

| Thickness (mm) | 5.0 to 50.0. |

| Width (mm) | 1000mm, 1200mm, 1250mm, 1500mm, 1800mm, 2000mm, 2200mm, and & customer-specific widths. |

| Length (mm) | 6m or 12m or customer-specific cut-to-length. |

| Surface treatment | Black, Oiled, Painted, Galvanized and so on |

Mechanical Properties Carbon Steel Plate

| Type of Carbon Steel Plates | Carbon Content | Tensile Strength | Yield Strength | Properties |

| Low/Mild Carbon Steel Plate | 0.05-0.25% | 325-500MPa | 180-260MPa | Low hardness; high ductility; low cost; good formability and weldability |

| Medium Carbon Steel Plate | 0.26-0.60% | 460-620MPa | 325-420MPa | Medium strength, ductility, and toughness; poor weldability |

| High Carbon Steel Plate | 0.61-1.50% | 660-940MPa | 380-440MPa | Greatest strength and hardness; low ductility and formability |

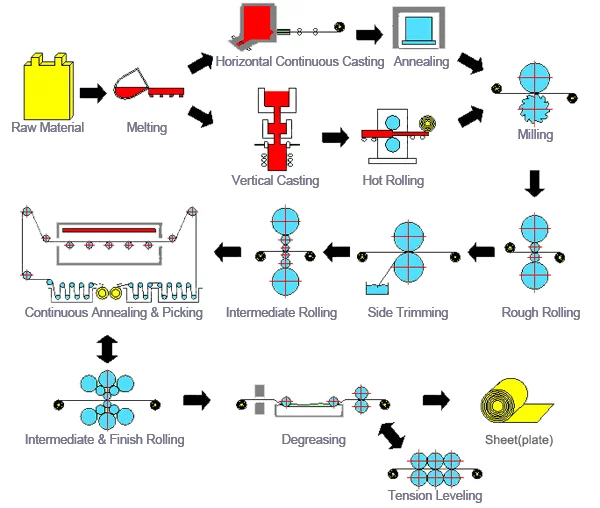

Manufacturing Process of Carbon Steel Plate

Application of Carbon Steel Plate

- Carbon Structural Steel Plate

It is mostly used in the construction industry and hence, the quality, durability, and performance have to be of the highest standard. They have to withstand overweight loads and pressure and must be corrosion-resistant. It is known by the name construction steel plate.

- Boiler Steel Plate

These are high-pressure carbon steel plates generally used in designing vessels, boilers, and heat containers. Carbon boiler steel plates have low corrosive properties and can withstand low heat. Several layers of either chromium or nickel are added to make it suitable for usage in various environments.

- Tanks Steel Plate

Carbon steel plates are used for building oil and gas tanks, storage tanks, water tanks, and tanks for storage of other all kinds of stuff.

- Carbon Shipbuilding Steel Plate

Carbon steel plates are in high demand especially from the oil and gas industry as they require thick carbon steel plates of extremely good quality. Most of these are made according to the specifications of the customers and the steel used is certified because a small lamellar tear can be fatal.

- Free-cutting Carbon Steel Plate

Carbon steel plate is a kind of steel plate that adds some elements to make the steel much brittle so that the steel plate is easily broken when cutting. It is beneficial to improve the cutting speed and prolong the life of the cutting tool.