OCTG Casing and Tubing Pipe

Details of OCTG Casing and Tubing Pipe

What is an OCTG Casing and Tubing Pipe?

OCTG is the acronym for Oil Country Tubular Goods. OCTG is a tube and pipe which is used in the production of oil and gas. This pipe is used both onshore and offshore for the production of oil and gas. Oil Country Tubular Goods is a collection of rolled metal products such as drill pipe, casing and tubing, line pipe, couplings, connections, and accessories that are useful in the production of oil and gas. These OCTG products are manufactured according to the specifications set by API (American Petroleum Institute). Under the API specifications, OCTG oil and gas pipe is graded under more than ten different grades, depending on their performance and the materials used. OCTG products can be either seamless or welded. They are available in different sizes and lengths. Bestar Steel offers both seamless and welded.

Chemical compositions of casing pipe

|

Standard |

Grade |

Chemical compositions(%) |

|||||||||

|

API SPEC 5CT |

J55 |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

Mo |

V |

|

K55 |

0.34~0.39 |

0.20~0.35 |

1.25~1.50 |

≤0.020 |

≤0.015 |

≤0.15 |

≤0.20 |

≤0.20 |

/ |

/ |

|

|

N80 |

0.34~0.38 |

0.20~0.35 |

1.45~1.70 |

≤0.020 |

≤0.015 |

≤0.15 |

/ |

/ |

/ |

0.11~0.16 |

|

|

L80 |

0.15~0.22 |

≤1.00 |

0.25~1.00 |

≤0.020 |

≤0.010 |

12.0~14.0 |

≤0.20 |

≤0.20 |

/ |

/ |

|

|

P110 |

0.26~0.395 |

0.17~0.37 |

0.40~0.70 |

≤0.020 |

≤0.010 |

0.80~1.10 |

≤0.20 |

≤0.20 |

0.15~0.25 |

≤0.08 |

|

Mechanical properties of casing pipe

|

Grade |

Type |

Total elongation under load (%) |

Yield strength (min)Mpa |

Yield strength (max)Mpa |

Tensile strength min Mpa |

Hardness Max (HRC) |

Hardness Max (HBW) |

|

J55 |

- |

0.5 |

379 |

552 |

517 |

- |

- |

|

K55 |

- |

0.5 |

379 |

552 |

655 |

- |

- |

|

N80 |

1 |

0.5 |

552 |

758 |

689 |

- |

- |

|

N80 |

Q |

0.5 |

552 |

758 |

689 |

- |

- |

|

L80 |

1 |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

L80 |

9Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

L80 |

13Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

C90 |

- |

0.5 |

621 |

724 |

689 |

25.4 |

255 |

|

C95 |

- |

0.5 |

655 |

758 |

724 |

- |

- |

|

T95 |

- |

0.5 |

655 |

758 |

724 |

25.4 |

255 |

|

P110 |

- |

0.6 |

758 |

965 |

862 |

- |

- |

|

Q125 |

All |

0.65 |

862 |

1034 |

931 |

- |

- |

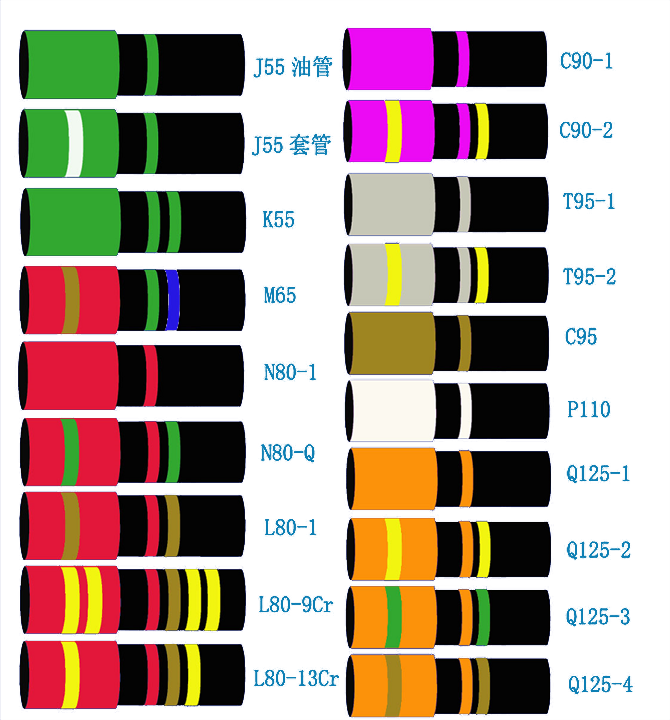

Color Codes for API 5CT Casing and Tubing

Size Chart of OCTG Casing and Tubing Pipe

Size table of casing pipe

| Outside Diameter (Inches) | Available Poundage (Pounds Per Foot) |

| 4-1/2 | 9.50 PPF to 15.10 PPF |

| 5 | 11.50 PPF to 24.10 PPF |

| 5-1/2 | 14.00 PPF to 43.10 PPF |

| 6-5/8 | 20.00 PPF to 32.00 PPF |

| 7 | 17.00 PPF to 57.10 PPF |

| 7-5/8 | 24.00 PPF to 55.30 PPF |

| 7-3/4 | 46.10 PPF |

| 8-5/8 | 24.00 PPF to 49.00 PPF |

| 9-5/8 | 32.30 PPF to 75.60 PPF |

| 10-3/4 | 32.75 PPF to 85.30 PPF |

| 11-3/4 | 42.00 PPF to 71.00 PPF |

| 13-3/8 | 48.00 PPF to 72.00 PPF |

| 16 | 65.00 PPF to 109.00 PPF |

| 18-5/8 | 87.50 PPF |

| 20 | 94.00 PPF to 133.00 PPF |

Size table of Tubing

| Outside Diameter (Inches) | Corresponding Poundage (Pounds Per Foot) |

| 1.050 | 1.14 PPF to 1.54 PPF |

| 1.315 | 1.70 PPF to 2.24 PPF |

| 1.660 | 2.09 PPF to 3.07 PPF |

| 1.900 | 2.40 PPF to 5.15 PPF |

| 2.063 | 3.24 PPF to 4.50 PPF |

| 2-3/8 | 4.00 PPF to 7.45 PPF |

| 2-7/8 | 6.40 PPF to 11.50 PPF |

| 3-1/2 | 7.70 PPF to 17.00 PPF |

| 4 | 9.50 PPF to 22.20 PPF |

| 4-1/2 | 12.60 PPF to 26.10 PPF |

Application of OCTG Casing and Tubing Pipe

- Unconventional

- Deepwater

- Shallow Water

- HP/HT & Deep Wells

- Horizontal & Extended Reach Wells

- Casing While Drilling

- Hermal (SAGD & CSS)

- TenarisHydril premium connections

- Internal coatings

- Premium sucker rods