Stainless Steel Seamless Pipe

Product Descripition

What is Stainless Steel Seamless Pipe

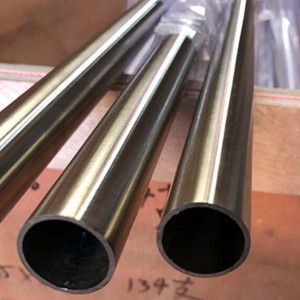

Low-cost and corrosion resistance material manufactured by stainless steel pipe. It's applied in various industries for different parts. Not only is it durable and long-lasting with a perfect surface finish, but it also has excellent strength.

Stainless steel is one of the popular and versatile materials. Stainless steel seamless pipe is widely used in commercial and industrial fields, especially fluid transportation. It has superior performance in high pressure, high strength, and corrosion resistance. That is used in applications where high-temperature strength and superior corrosion resistance and critical. Further, stainless steel is easy to clean and doesn't tarnish. The highest pressure resistance is characterized by seamless stainless pipes made of a steel rod drilled along the length of the pipe, which is how pipes for the production of firearms barrels are made.

Product Specification

Available Specification

| Product Name | Executive Standard | Dimension | Steel Code / Steel Grade |

| Seamless Austenitic Stainless Steel Pipes | ASTM A312/A312M, ASME SA312/SA312M | OD: 1/4"~20" WT: SCH5S~SCH80S |

TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| Seamless Austenitic Stainless Steel Tubing for General Service | ASTM A269, ASME SA269 | OD: 6.0~50.8mm WT: 0.8~10.0mm |

TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| Seamless Austenitic Alloy-Steel Boiler, Super Heater, and Heat-Exchanger Tubes | ASTM A213/A213M, ASME SA213/SA213M | OD: 6.0~50.8mm WT: 0.8~10.0mm |

TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| Seamless Duplex Stainless Steel Tubing for General Service | ASTM A789 / A789M | OD: 19.0~60.5mm WT: 1.2~5.0mm |

S31803, S32205, S32750 |

| Seamless Duplex Stainless Steel Pipes | ASTM A790 / A790M | OD: 3/4"~10" WT: SCH5S~SCH80S |

S31803, S32205, S32750 |

| Seamless Stainless Steel Mechanical Tubing | ASTM A511 | OD: 6.0~50.8mm WT: 1.8~10.0mm |

MT304, MT304L, MT304H, MT310, MT310S, MT316, MT316L, MT317, MT317L, MT321, MT321H, MT347 |

| Seamless Stainless Steel Tubes for Pressure Purposes | EN 10216, DIN 17456, 17458 | OD: 6.0~530.0mm WT: 0.8~34.0mm |

1.4301, 1.4307, 1.4541, 1.4401, 1.4404, 1.4571, 1.4878, 1.4432, 1.4462 |

Chemical Composition

Chemical Composition of ASTM A213 Stainless Steel Seamless Pipe

| Grade | UNS Designation |

Composition | |||||||

| Carbon | Manganese | Phosphorous | Sulfur | Silicon | Chromium | Nickel | Molybdenum | ||

| C | S25700 | 0.02 | 2.00 | 0.025 | 0.010 | 6.5-8.0 | 8.0-11.5 | 22.0-25.0 | 0.50 |

| TP304 | S30400 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-11.0 | ... |

| TP304L | S30403 | 0.035D | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-12.0 | ... |

| TP304H | S30409 | 0.04–0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-11.0 | ... |

| C | S30432 | 0.07–0.13 | 0.50 | 0.045 | 0.030 | 0.03 | 17.0-19.0 | 7.5-10.5 | ... |

| TP304N | S30451 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-11.0 | ... |

| TP304LN | S30453 | 0.035D | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-11.0 | ... |

| C | S30615 | 0.016–0.24 | 2.00 | 0.030 | 0.030 | 3.2-4.0 | 17.0-19.5 | 13.5-16.0 | ... |

| C | S30815 | 0.05–0.10 | 0.80 | 0.040 | 0.030 | 1.40-2.00 | 20.0-22.0 | 10.0-12.0 | ... |

| TP316 | S31600 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.00–3.00 |

| TP316L | S31603 | 0.035D | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.00–3.00 |

| TP316H | S31609 | 0.04–0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 11.0-14.0 | 2.00–3.00 |

| TP316N | S31651 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-13.0 | 2.00–3.00 |

| TP316LN | S31653 | 0.035D | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-13.0 | 2.00–3.00 |

Chemical Composition of ASTM A312 Stainless Steel Seamless Pipe

| Grade | UNS Designation |

Composition | |||||||

| Carbon | Manganese | Phosphorous | Sulfur | Silicon | Chromium | Nickel | Molybdenum | ||

| TP304 | S30400 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0 – 20.00 | 8.0-11.0 | ... |

| TP304L | S30403 | 0.035 D | 2.00 | 0.045 | 0.03 | 1.00 | 18.0 – 20.00 | 8.0-113.0 | ... |

| TP304H | S30409 | 0.04 – 0.10 | 2.00 | 0.045 | 0.03 | 1.00 | 18.0 – 20.00 | 8.0-11.0 | ... |

| ... | S30415 | 0.04 – 0.06 | 0.8 | 0.045 | 0.03 | 1.00 –2.00 | 18.0 – 19.0 | 9.0-10.0 | ... |

| TP304N | S30451 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 18.0 – 20.00 | 8.0-18.0 | ... |

| TP304LN | S30453 | 0.035 | 2.00 | 0.045 | 0.03 | 1.00 | 18.0 – 20.00 | 8.0-12.0 | ... |

| TP316 | S31600 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 16.0-18.0 | 11.0-14.0E | ... |

| TP316L | S31603 | 0.035 D | 2.00 | 0.045 | 0.03 | 1.00 | 16.0-18.0 | 10.0-14.0 | ... |

| TP316H | S31609 | 0.04 – 0.10 | 2.00 | 0.045 | 0.03 | 1.00 | 16.0-18.0 | 10.0-14.0E | ... |

| TP316Ti | S31635 | 0.08 | 2.00 | 0.045 | 0.03 | 0.75 | 16.0-18.0 | 10.0-14.0 | 53 (C+N) –0.70 |

| TP316N | S31651 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 16.0-18.0 | 11.0-14.0E | ... |

| TP316LN | S31635 | 0.035 | 2.00 | 0.045 | 0.03 | 1.00 | 16.0-18.0 | 11.0-14.0E | ... |

Mechanical Properties

Mechanical Properties of ASTM A213 Stainless Steel Seamless Pipe

| Grade | UNS Designation |

Tensile Strength min, ksi [MPa] |

Yield Strength, min, ksi [MPa] |

| TP304 | S30400 | 75[515] | 30[205] |

| TP304L | S30403 | 70[485] | 25[170] |

| TP304H | S30409 | 75[515] | 30[205] |

| ... | S30432 | 80[550] | 30[205] |

| TP304N | S30451 | 80[550] | 35[240] |

| TP304LN | S30453 | 75[515] | 30[205] |

| TP316 | S31600 | 75[515] | 30[205] |

| TP316L | S31603 | 70[485] | 25[170] |

| TP316H | S31609 | 75[515] | 30[205] |

| TP316N | S31651 | 80[550] | 35[240] |

Mechanical Properties of ASTM A312 Stainless Steel Seamless Pipe

| Grade | UNS Designation |

Tensile Strength min, ksi [MPa] |

Yield Strength, min, ksi [MPa] |

| TP304 | S30400 | 75[515] | 30[205] |

| TP304L | S30403 | 70[485] | 25[170] |

| TP304H | S30409 | 75[515] | 30[205] |

| . . . | S30415 | 87[600] | 42[290] |

| TP304N | S30451 | 80[550] | 35[240] |

| TP304LN | S30453 | 75[515] | 30[205] |

| TP316 | S31600 | 75[515] | 30[205] |

| TP316L | S31603 | 70[485] | 25[170] |

| TP316H | S31609 | 75[515] | 30[205] |

| . . . | S31635 | 75[515] | 30[205] |

| TP316N | S31651 | 80[550] | 35[240] |

| TP316LN | S31653 | 75[515] | 30[205] |

Application

Stainless steel seamless pipe can resist high temperatures for cleanliness and maintain the purity of materials which contact stainless steel directly. Stainless steel pipe and tubing are used in chemical plants, aviation fields, marine equipment, cryogenic transportation, medical and architectural industries.

- Chemical plants

- Aviation fields

- Marine equipment

- Cryogenic transportation

- Medical & architectural industries

Size chart of stainless steel seamless pipe

| Nominal | OD | Sch 5S | Sch 10S | Sch-40S | Sch-80S | Sch-160S | Sch-XXS | |||||||

| mm | inch | mm | WT mm | Weight Kg/mt | WT mm | Weight Kg/mt | WT mm | Weight Kg/mt | WT mm | Weight Kg/mt | WT mm | Weight Kg/mt | WT mm | Weight Kg/mt |

| 3 | 1/8 | 10.3 | 1.24 | 0.276 | 1.24 | 0.28 | 1.73 | 0.37 | 2.41 | 0.47 | - | - | - | - |

| 6 | 1/4 | 13.7 | 1.24 | 0.39 | 1.65 | 0.49 | 2.24 | 0.631 | 3.02 | 0.8 | - | - | - | - |

| 10 | 3/8 | 17.1 | 1.24 | 0.49 | 1.65 | 0.63 | 2.31 | 0.845 | 3.2 | 1.1 | - | - | - | - |

| 15 | 1/2 | 21.3 | 1.65 | 0.8 | 2.11 | 1 | 2.77 | 1.27 | 3.75 | 1.62 | 4.75 | 1.94 | 7.47 | 2.55 |

| 20 | 3/4 | 26.7 | 1.65 | 1.03 | 2.11 | 1.28 | 2.87 | 1.68 | 3.91 | 2.2 | 5.54 | 2.89 | 7.82 | 3.63 |

| 25 | 1 | 33.4 | 1.65 | 1.3 | 2.77 | 2.09 | 3.38 | 2.5 | 4.55 | 3.24 | 6.35 | 4.24 | 9.09 | 5.45 |

| 32 | 1.25 | 42.2 | 1.65 | 1.65 | 2.77 | 2.7 | 3.56 | 3.38 | 4.85 | 4.47 | 6.35 | 5.61 | 9.7 | 7.77 |

| 40 | 1.5 | 48.3 | 1.65 | 1.91 | 2.77 | 3.11 | 3.68 | 4.05 | 5.08 | 5.41 | 7.14 | 7.25 | 10.16 | 9.54 |

| 50 | 2 | 60.3 | 1.65 | 2.4 | 2.77 | 3.93 | 3.91 | 5.44 | 5.54 | 7.48 | 8.74 | 11.1 | 11.07 | 13.44 |

| 65 | 2.5 | 73 | 2.11 | 3.69 | 3.05 | 5.26 | 5.16 | 8.63 | 7.01 | 11.4 | 9.53 | 14.9 | 14.2 | 20.39 |

| 80 | 3 | 88.9 | 2.11 | 4.51 | 3.05 | 6.45 | 5.49 | 11.3 | 7.62 | 15.2 | 11.1 | 21.3 | 15.24 | 27.65 |

| 100 | 4 | 114.3 | 2.11 | 5.84 | 3.05 | 8.36 | 6.02 | 16.07 | 8.56 | 22.3 | 13.49 | 33.54 | 17.12 | 41.03 |

| 125 | 5 | 141.3 | 2.77 | 9.47 | 3.4 | 11.57 | 6.55 | 21.8 | 9.53 | 31.97 | 15.88 | 49.11 | 19.05 | 57.43 |

| 150 | 6 | 168.3 | 2.77 | 11.32 | 3.4 | 13.84 | 7.11 | 28.3 | 10.97 | 42.7 | 18.2 | 67.56 | 21.95 | 79.22 |

| 200 | 8 | 219.1 | 2.77 | 14.79 | 3.76 | 19.96 | 8.18 | 42.6 | 12.7 | 64.6 | 23 | 111.2 | 22.23 | 107.8 |

| 250 | 10 | 273.1 | 3.4 | 22.63 | 4.19 | 27.78 | 9.27 | 60.5 | 12.7 | 96 | 28.6 | 172.4 | 25.4 | 155.15 |

| 300 | 12 | 323.9 | 3.96 | 31.25 | 4.57 | 36 | 9.52 | 73.88 | 12.7 | 132 | 33.32 | 238.76 | 25.4 | 186.97 |

| 350 | 14 | 355.6 | 3.96 | 34.36 | 4.78 | 41.3 | 11.13 | 94.59 | 19.05 | 158.08 | 35.71 | 281.7 | - | - |

| 400 | 16 | 406.4 | 4.19 | 41.56 | 4.78 | 47.29 | 12.7 | 123.3 | 21.41 | 203.33 | 40.46 | 365.11 | - | - |

| 450 | 18 | 457.2 | 4.19 | 46.8 | 4.78 | 53.42 | 14.27 | 155.8 | 23.8 | 254.36 | 45.71 | 466.4 | - | - |

| 500 | 20 | 508 | 4.78 | 59.25 | 5.54 | 68.71 | 15.09 | 183.42 | 26.19 | 311.2 | 49.99 | 564.68 | - | - |

| 600 | 24 | 609.6 | 5.54 | 82.47 | 6.35 | 94.45 | 17.48 | 255.41 | 30.96 | 442.08 | 59.54 | 808.22 | - | - |

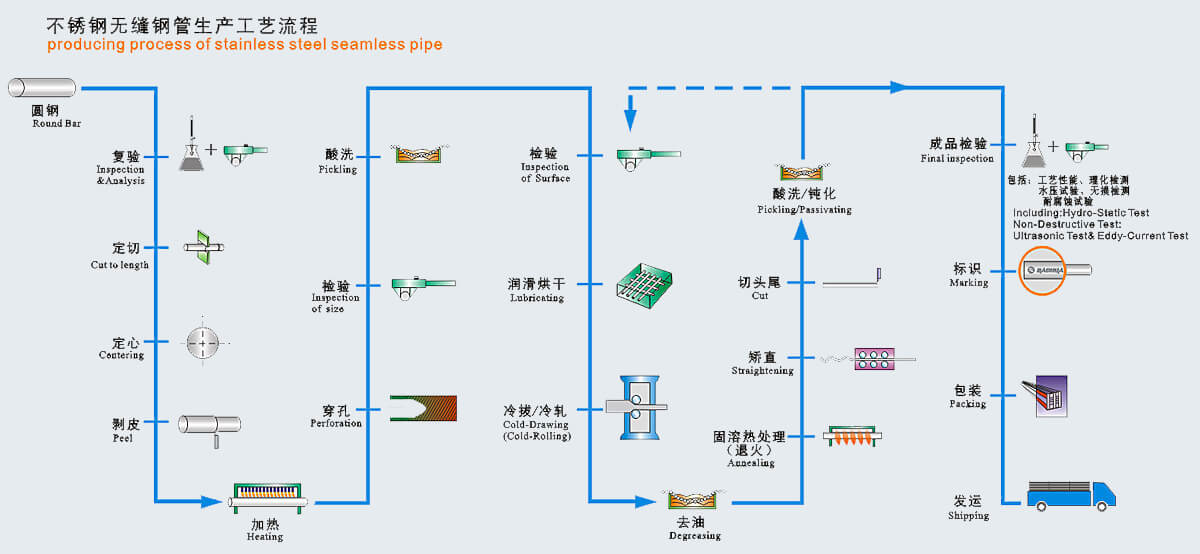

Manufacturing Process of Stainless Steel Seamless Pipe