316 Pipe

Product Descripition

What is 316 Pipe

Stainless Steel 316 Pipe is an austenitic stainless steel grade pipe that has good resistance to chloride ion corrosion stress cracking. Stainless steel 316 pipe has excellent forming and welding characteristics. It is readily brake or roll formed into a variety of parts for applications in the industrial, architectural, and transportation fields. Stainless steel 316 pipe also has outstanding welding characteristics. Post-weld annealing is not required when welding thin sections. The austenitic structure also gives these grades excellent toughness, even down to cryogenic temperatures. Bestar Steel is a leading supplier and manufacturer of Stainless Steel 316 Pipe products in various scales and dimensions.

Product Specification

What is the specification of 316 pipe

Standard of 316 pipe:

ASTM A213; ASTM A269; ASTM A312; ASTM A632; ASME SA213; NFA 49-117;BS 10216

Size Range of 316 pipe:

Seamless steel pipe: OD: Φ3-Φ600mm; WT: 0.5-100mm; Length: 24000mm

Welded steel pipe: OD: Φ6-Φ1219mm; WT: 0.3-45mm; Length: 18000mm

Chemical Composition

Chemical Composition of ASTM A312 Stainless Steel 316 Pipe

| Grade | UNS Designation |

Composition | |||||||

| Carbon | Manganese | Phosphorous | Sulfur | Silicon | Chromium | Nickel | Molybdenum | ||

| TP316 | S31600 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.00–3.00 |

| TP316L | S31603 | 0.035D | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.00–3.00 |

| TP316H | S31609 | 0.04–0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 11.0-14.0 | 2.00–3.00 |

| TP316N | S31651 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-13.0 | 2.00–3.00 |

| TP316LN | S31653 | 0.035D | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-13.0 | 2.00–3.00 |

Mechanical Properties

Mechanical Properties of ASTM A312 Stainless Steel 316 Pipe

| Grade | UNS Designation |

Tensile Strength min, ksi [MPa] |

Yield Strength, min, ksi [MPa] |

| TP316 | S31600 | 75[515] | 30[205] |

| TP316L | S31603 | 70[485] | 25[170] |

| TP316H | S31609 | 75[515] | 30[205] |

| . . . | S31635 | 75[515] | 30[205] |

| TP316N | S31651 | 80[550] | 35[240] |

| TP316LN | S31653 | 75[515] | 30[205] |

Application

316 pipe application

- Chemical: chemical containers, pressure vessels, and industrial equipment

- Water treatment: woven or welded screens for water filtration

- Pulp and paper: used in paper machines to avoid iron contamination.

- Automotive: threaded fasteners, springs, and furnace parts

- Medical: Medical equipment and orthopedic implants

- Dental: Dental implants, orthodontic appliances, and various dental instruments

- Semiconductor: semiconductor manufacturing equipment and cleanroom environments

- Food processing: food preparation surfaces, equipment, and appliances

- Aerospace: aircraft structures, fasteners, turbine blades, and exhaust systems

Size Chart of Stainless Steel 316 Pipe

|

OD |

OD Tolerance |

Wall Tolerance |

|

≤ .500” |

± .005” |

± 10% |

|

.500”–1.500” excl |

± .005” |

± 10% |

|

1.500”–3.500” excl |

± .010” |

± 10% |

|

3.500”–5.500” excl |

± .015” |

± 10% |

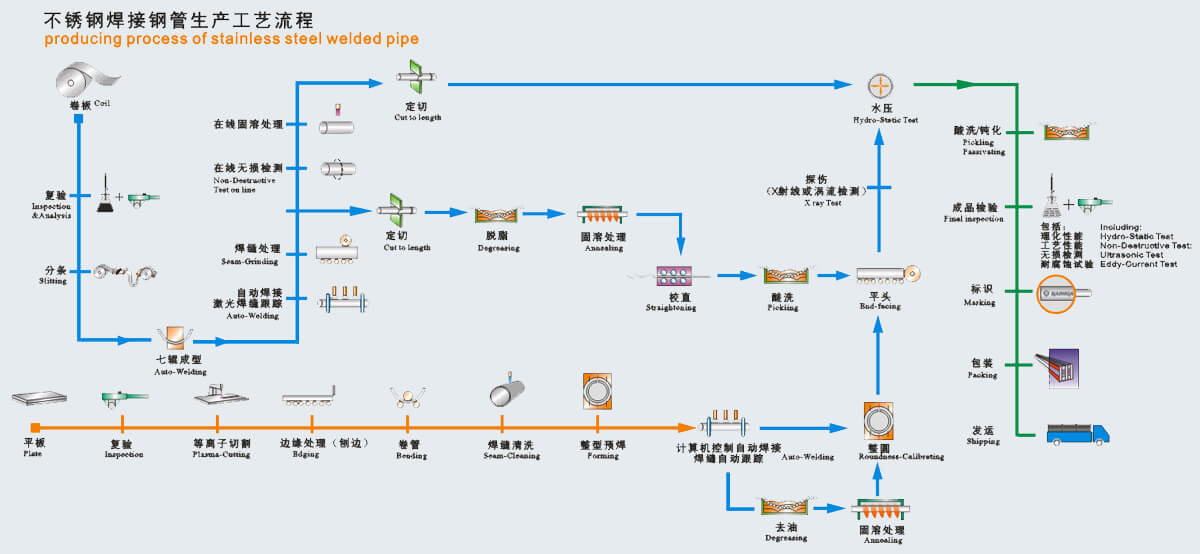

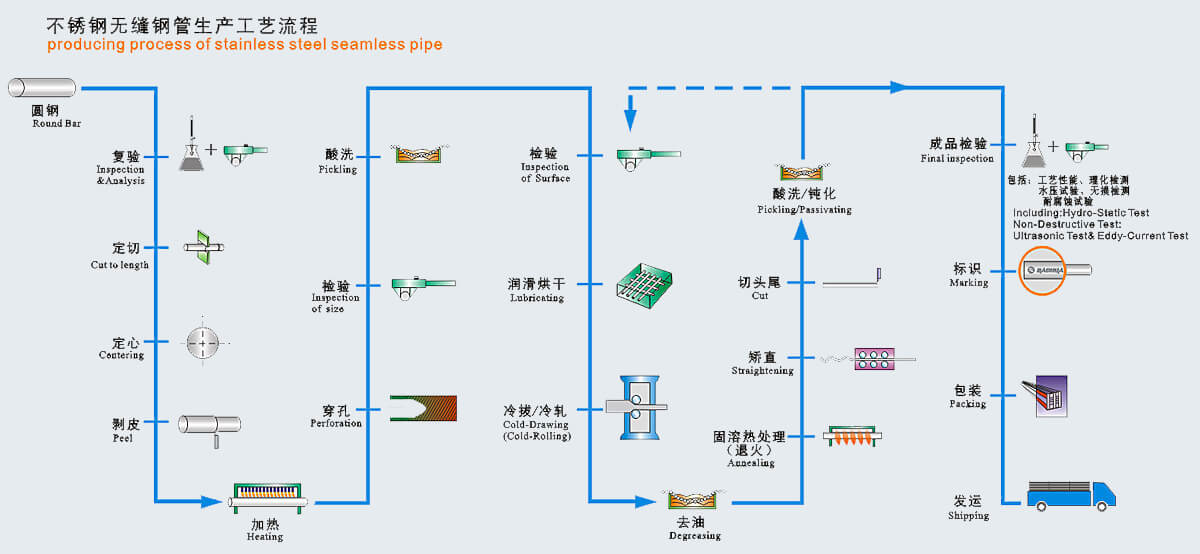

Manufacturing Process of Stainless Steel 316 Pipe:

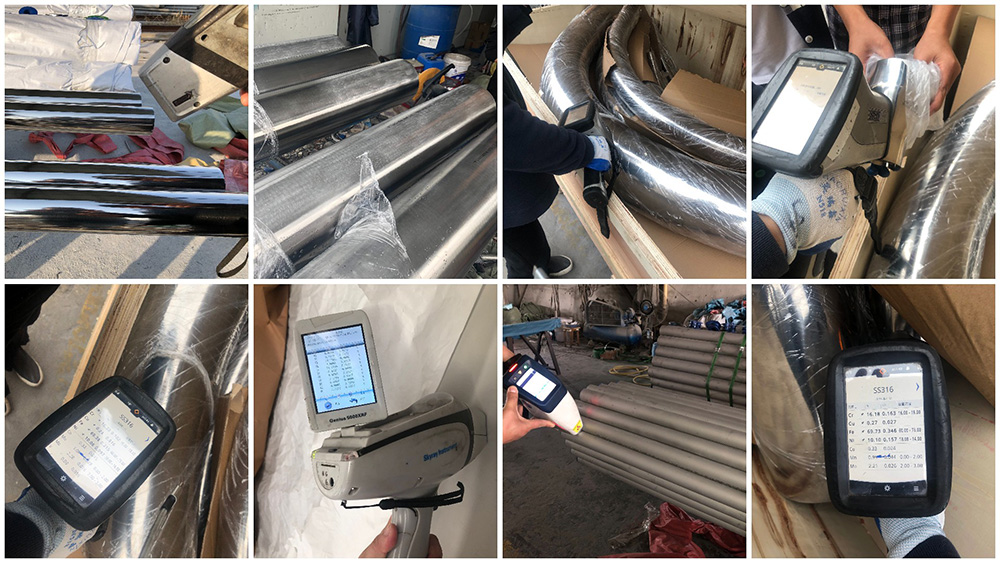

Test:

PMI test