Carbon Steel Seamless Pipe

Details of Carbon Steel Seamless Pipe

What is a Carbon Steel Seamless Pipe?

Carbon steel seamless pipes are also called CS pipes. The general carbon steel seamless pipe is made of 10, 20, 30, 35, 45, and other high-quality carbon steel 16Mn, 5MnV and other low-alloy structural steel or 40Cr, 30CrMnSi, 45Mn2, 40MnB, and other alloy steel hot-rolled or Cold rolled. Seamless pipes made of low carbon steel such as 10 and 20 are mainly used for fluid conveying pipes. 45, 40Cr and other medium carbon steel seamless pipes are used to make mechanical parts, such as the force parts of automobiles and tractors.

Chemical Composition of Carbon Steel Seamless Pipe

Chemical Composition of Carbon Steel Seamless Pipe

| Standard | Grade | Chemical Composition (%) | ||||

| ASTM A53 | C | Si | Mn | P | S | |

| A | ≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.06 | |

| B | ≤0.30 | - | ≤1.2 | ≤0.05 | ≤0.06 | |

| ASTM A106 | A | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 |

| B | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | |

| ASTM A179 | A179 | 0.06-0.18 | - | 0.27-0.63 | ≤0.035 | ≤0.035 |

| ASTM A192 | A192 | 0.06-0.18 | ≤0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 |

| API 5L PSL1 | A | 0.22 | - | 0.9 | 0.03 | 0.03 |

| B | 0.28 | - | 1.2 | 0.03 | 0.03 | |

| X42 | 0.28 | - | 1.3 | 0.03 | 0.03 | |

| X46 | 0.28 | - | 1.4 | 0.03 | 0.03 | |

| X52 | 0.28 | - | 1.4 | 0.03 | 0.03 | |

| X56 | 0.28 | - | 1.4 | 0.03 | 0.03 | |

| X60 | 0.28 | - | 1.4 | 0.03 | 0.03 | |

| X65 | 0.28 | - | 1.4 | 0.03 | 0.03 | |

| X70 | 0.28 | - | 1.4 | 0.03 | 0.03 | |

| API 5L PSL2 | B | 0.24 | - | 1.2 | 0.025 | 0.015 |

| X42 | 0.24 | - | 1.3 | 0.025 | 0.015 | |

| X46 | 0.24 | - | 1.4 | 0.025 | 0.015 | |

| X52 | 0.24 | - | 1.4 | 0.025 | 0.015 | |

| X56 | 0.24 | - | 1.4 | 0.025 | 0.015 | |

| X60 | 0.24 | - | 1.4 | 0.025 | 0.015 | |

| X65 | 0.24 | - | 1.4 | 0.025 | 0.015 | |

| X70 | 0.24 | - | 1.4 | 0.025 | 0.015 | |

| X80 | 0.24 | - | 1.4 | 0.025 | 0.015 | |

Mechanical Properties of Carbon Steel Seamless Pipe

Mechanical Properties of Carbon Steel Seamless Pipe

| Standard | Grade | Mechanical Properties | |

| ASTM A53 | Tensile Strength(Mpa) | Yield Strength(Mpa) | |

| A | ≥330 | ≥205 | |

| B | ≥415 | ≥240 | |

| ASTM A106 | A | ≥415 | ≥240 |

| B | ≥485 | ≥275 | |

| ASTM A179 | A179 | ≥325 | ≥180 |

| ASTM A192 | A192 | ≥325 | ≥180 |

| API 5L PSL1 | A | ≥331 | ≥207 |

| B | ≥414 | ≥241 | |

| X42 | ≥414 | ≥290 | |

| X46 | ≥434 | ≥317 | |

| X52 | ≥455 | ≥359 | |

| X56 | ≥490 | ≥386 | |

| X60 | ≥517 | ≥448 | |

| X65 | ≥531 | ≥448 | |

| X70 | ≥565 | ≥483 | |

| API 5L PSL2 | B | ≥414 | ≥241 |

| X42 | ≥414 | ≥290 | |

| X46 | ≥434 | ≥317 | |

| X52 | ≥455 | ≥359 | |

| X56 | ≥490 | ≥386 | |

| X60 | ≥517 | ≥414 | |

| X65 | ≥531 | ≥448 | |

| X70 | ≥565 | ≥483 | |

| X80 | ≥621 | ≥552 | |

Product Specification and Size

| ASTM / ASME | |||

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Black and Hot-Dipped Zinc-Coated Seamless Steel Pipes | ASTM A53 | Ø10.3~1200 x WT1.0~150 | Gr.A, Gr.B, Gr.C |

| Seamless Carbon Steel Pipes for High Temperature Service | ASTM A106 | Ø10.3~1200 x WT1.0~150 | Gr.B, Gr.C |

| Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes | ASTM A179 | Ø10.3~426 x WT1.0~36 | Low Carbon Steel |

| Seamless Carbon Steel Boiler Tubes for High Pressure | ASTM A192 | Ø10.3~426 x WT1.0~36 | Low Carbon Steel |

| Seamless Cold-Drawn Intermediate Alloy Steel Heat-Exchanger and Condenser Tubes | ASTM A199 | Ø10.3~426 x 1.0~36 | T5, T22 |

| Seamless Medium-Carbon Steel Boiler and Superheater Tubes | ASTM A210 | Ø10.3~426 x WT1.0~36 | A1, C |

| Seamless Ferritic and Austenitic Alloy Steel Boiler, Superheater and Heat-Exchanger Tubes | ASTM A213 | Ø10.3~426 x WT1.0~36 | T5, T9, T11, T12, T22, T91 |

| Seamless Carbon and Alloy Steel for Mechanical Tubing | ASTM A333 | Ø1/4"~42" x WT SCH20~XXS | Gr.1, Gr.3, Gr.6 |

| Seamless and Welded Carbon Steel Pipes and Alloy Steel Pipes for Low Temperature Use | ASTM A334 | Ø1/4"~4" x WT SCH20~SCH80 | Gr.1, Gr.6 |

| Seamless Cold-Drawn Carbon Steel Feedwater Heater Tubes | ASTM A556 | Ø10.3~426 x WT1.0~36 | A2, B2 |

| DIN | |||

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Seamless Steel Tubes for Elevated Temperature | DIN 17175 | Ø10~762 x WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| Seamless Steel Tubes | DIN 1629 / DIN 2391 | Ø13.5~762 x WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| Seamless Steel Tubes | DIN 2440 | Ø13.5~165.1 x WT1.8~4.85 | St33.2 |

| Seamless Steel Pipes for Structural Purpose | DIN 2393 | Ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| BS | |||

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Seamless Steel Tubes for Machine Structure | BS 970 | Ø10~762 x WT1.0~120 | Carbon Steel |

| Seamless Steel Tubes for Boiler and Heat Exchangers | BS 3059 | Ø10~762 x WT1.0~120 | 360, 410, 440, 460, 490 |

Uses

| Chilled water pipe | Steam/condensate pipe | Heat exchanger pipe | Marine/offshore pipe | Dredging pipe | Industrial pipe |

| Oil and gas pipe | Fire fighting pipe | Construction/structure pipe | Irrigation pipe | Drain/sewage pipe | Boiler tube |

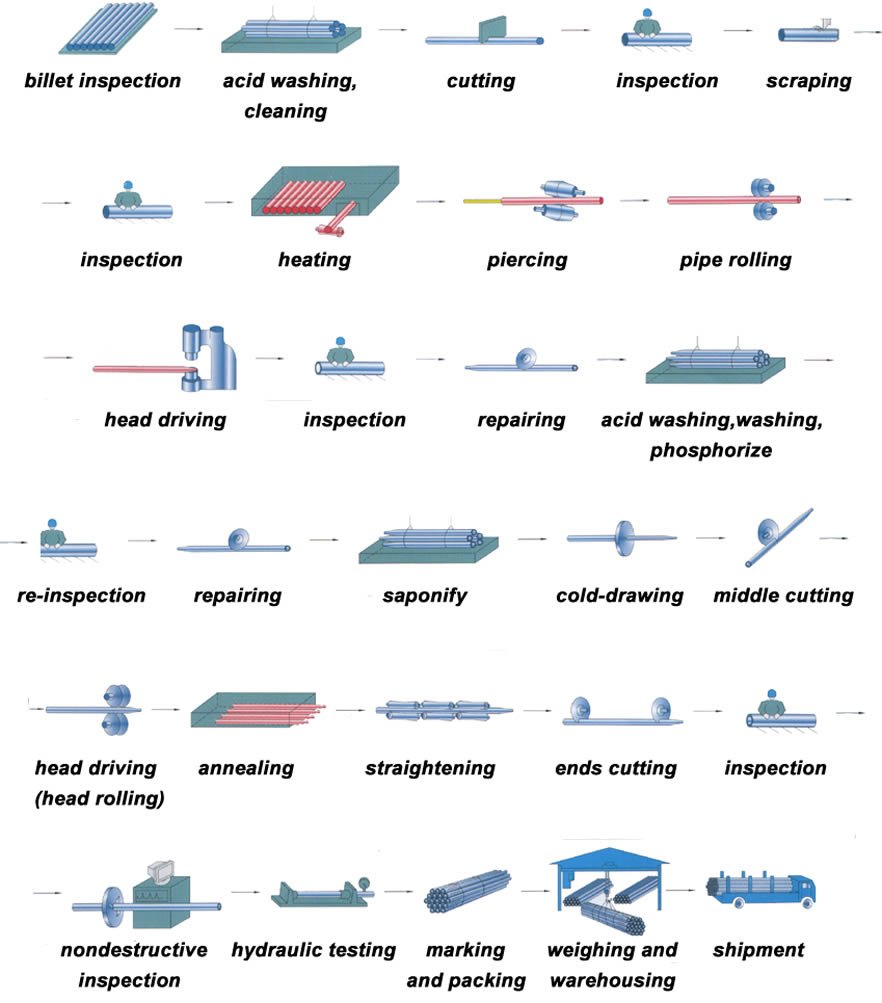

Manufacturing Process of Carbon Steel Seamless Pipe

Application of Carbon Steel Seamless Pipe

Carbon steel seamless pipes are extensively applied in the nuclear device, gas conveyance, petrochemical, shipbuilding and boiler industries, with characteristics of high corrosion resistance combined with suitable mechanical properties.

- Nuclear device

- Gas conveyance

- Petrochemical industries

- Shipbuilding and boiler industries