News

-

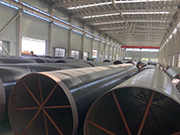

Internal and external epoxy powder coated straight seam steel pipe details

Weld grade requirements for internal and external epoxy powder coated straight seam steel pipes: The weld grade requirements for internal and external epoxy powder coated straight seam steel pipes are generally related to the pipe use and working environment. There will be corresponding requireme...Read more -

High-pressure boiler steel tube—related details

Knowledge related to high-pressure boiler steel pipes – high-pressure boiler steel pipes: mainly used to manufacture high-quality carbon structural steel, alloy structural steel, and stainless heat-resistant steel seamless steel pipes for steam boiler steel pipes with high pressure and abov...Read more -

What Are The Carbon Steel Pipe Properties?

Carbon steel pipes are made from an iron and carbon alloy, making them strong, durable, and resistant to corrosion and oxidation. Due to their strength and ability to withstand pressure, they are widely used in heavy industries. This article will provide more information on the characteristics of...Read more -

Uses Of Carbon Steel Pipe Fittings

Carbon steel pipe fittings have a wide range of applications in various fields such as industry, construction, energy, and chemicals. They are used to connect, divert, and control piping systems to meet the diverse needs of fluid, gas, and solid transfer. Below are some of the primary uses of car...Read more -

304 stainless steel thick wall steel pipe introduction:

304 stainless steel thick-walled steel pipes refer to stainless steel pipes with a wall thickness of 10-50.0mm. Those with a thickness of 50mm or more are called extra-thick-walled stainless steel pipes. 304 stainless steel thick-walled steel pipe is a versatile stainless steel material with stro...Read more -

Carbon Steel Pipe VS Black Steel Pipe

Currently, carbon steel pipe and black steel pipe are both widely used in various industries. Currently, carbon steel pipe and black steel pipe are both widely used in various industries. However, what distinguishes these two types of pipes? Currently, carbon steel pipe and black steel pipe are b...Read more