Products News

-

Why 316 stainless steel is better than 304 stainless steel

Stainless steel is a common metal material. Because of its strong corrosion resistance, beautiful appearance, easy cleaning, stable structure, and other characteristics, it is widely used in construction, chemical industry, medical treatment, food processing, environmental protection, and other f...Read more -

Performance, application, and market prospects of 304 stainless steel pipe

First, an overview of 304 stainless steel pipe 304 stainless steel pipe is a stainless steel pipe that has attracted widespread attention for its excellent corrosion resistance, high-temperature strength, and processing performance. The main components of 304 stainless steel pipe include iron, ch...Read more -

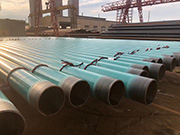

The uses and advantages of anti-corrosion steel pipes

Uses of anti-corrosion steel pipes: The base materials of anti-corrosion steel pipes include spiral pipes, straight seam pipes, seamless pipes, etc., which are widely used in long-distance water transportation, petroleum, chemical industry, natural gas, heat, sewage treatment, water sources, brid...Read more -

What impact does the hot rolling process have on metal materials

The impact of the hot rolling process on metal materials can be said to be far-reaching and extensive. First of all, the hot rolling process can significantly change the structure of metal materials, causing corresponding phase changes under different temperature and pressure conditions. This pha...Read more -

What are the precautions for stainless steel passivation treatment

Stainless steel passivation treatment is a commonly used surface treatment method aimed at improving the corrosion resistance and aesthetics of stainless steel. When performing stainless steel passivation treatment, some precautions need to be paid attention to to ensure treatment effect and safe...Read more -

How does the hot-rolled steel pipe process affect the quality of steel pipe

The impact of hot-rolled steel pipe technology on steel pipe quality is mainly reflected in the following aspects: 1. Rolling temperature: Rolling temperature is one of the most important parameters in the hot rolling process. If the temperature is too high, the steel may overheat, oxidize, or ev...Read more