News

-

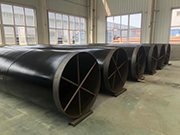

Detail of epoxy resin anti-corrosion steel pipe

1. Composition of epoxy resin anti-corrosion steel pipe: ①. Steel pipes: seamless steel pipes, straight seam steel pipes, spiral steel pipes and other steel pipes ②.Epoxy resin coating This product is a two-component, high-solid coating made of epoxy resin as the main agent. Divided into primer a...Read more -

How To Prevent Gap Corrosion of Stainless Steel Pipe?

Gaps may form between the surface of stainless steel pipes and deposits due to equipment and component structures or the presence of metal or non-metallic deposits. This can lead to punctate and ulcerative damage caused by crevice corrosion when exposed to corrosive media. In the presence of wate...Read more -

How can we extend the service life of spiral steel pipes

1. Spiral steel pipes must not be stacked together with acid, alkali, salt, cement, and other materials that are corrosive to steel in the warehouse. Different types of steel should be stacked separately to prevent confusion and contact corrosion; 2. Large steel sections, rails, steel plates, lar...Read more -

ASTM A312 Steel Pipe Size Tolerance

ASTM A312 is a standard specification for seamless, welded, and heavily cold worked austenitic stainless steel pipes. It is used in high-temperature and general corrosive service. This specification covers a wide range of pipe sizes and dimensions, and it includes specific size tolerances to ensu...Read more -

Reasons for uneven anti-corrosion thickness of 3PE anti-corrosion steel pipes

The industry standard SY/T0413-2002 does not stipulate the uniformity of thickness. It stipulates the low thickness value of the coating but requires that the low thickness value of the coating cannot be lower than the thickness value of the low point, rather than the thickness value of multiple ...Read more -

Heat Treatment of LSAW Steel Pipe

LSAW steel pipes are frequently used in industry. Heat treatment is a crucial step in their manufacturing process to improve their mechanical properties and ensure proper performance. The heat treatment processes for LSAW steel pipes include normalization, stress relief, quenching, and tempering....Read more